While the wax worms are continuing to pupate into wax moths and lay eggs I am continuing my investigation into how to use bee's wax in place of the oats in the LD50 experiment.

Since the 96 well polystyrene plates with the wax in them would need to be heated to too high of a temperature in order to melt the wax I am moving on to other methods.

My initial plan was to melt the bee's wax inside of a larger container and then quickly pipet the liquid wax to the wells. A small block of bee's wax was placed inside an Eppendorf tube and PCR tube (seen below) and heated in a water bath at 60C for 1 hour. However, at this temperature the wax did not melt and still appeared as the first picture below. By increasing the temperature to 70-80C the wax melted in almost 30 seconds after being placed inside the water. The melted wax inside the tubes is also seen below.

|

| Solid bee's wax inside Eppendorf and PCR tubes |

|

| Melted bee's wax after incubating at 70-80C for 30 seconds in a water bath |

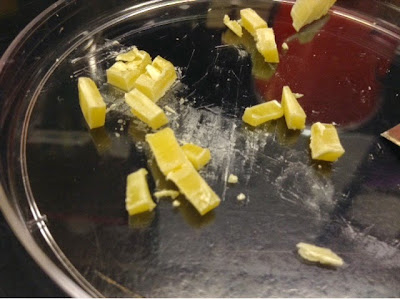

Small slabs of bee's wax was cut using a razor blade as seen below and transferred to a well in a 96 well polypropylene PCR plate (also seen below).

|

| Cut bee's wax to be put into 96 well plate |

|

| 96 well polypropylene PCR plate |

There were some air bubbles below the wax in some of the wells when the wax wasn't initially pushed all the way to the bottom of the well. Also, as soon as the plate of melted wax was removed from the water bath the wax solidified (almost) instantly. The wax was still soft enough to easily poke a hole through it with a toothpick. Now that I have a method to melt the wax, I need to determine a way to incorporate the spores without destroying them in the process (due to heat).

//EWW

No comments:

Post a Comment